"Traditional pipeline inspection relies on person, which is inefficient and incomplete. Now or in the future, cctv pipe crawler add AI function may be able to automatically identify defects such as cracks and corrosion with more than 95% accuracy rate"

What industry problems does AI solve for cctv pipe crawler robots?

Q1: What are the main difficulties of traditional pipeline inspection?

- Low manual efficiency: Only 100-200 meters of pipeline conditions can be inspected and analyze per hour, and fatigue errors are easy to occur.

- Strong subjectivity: Different inspectors have different judgment criteria for cracks, blockages, and damage levels.

- High hidden costs: Missed inspections may lead to subsequent repair costs such as pipeline ruptures.

Q2: How does AI optimize this process?

- Automatically mark defects: Real-time marking of cracks, rust, deformation, blockage, welds, etc. through deep learning models.

- Quantify damage levels: Automatically generate inspection reports based on parameters such as width and length.

- 7×24 hours work: No need to rest, greatly improving detection coverage.

The technical core of intelligent identification

Q3: How does AI identify damage in pipelines?

- Data collection stage: pipe defects (cracks, damage, blockage, etc.) Pictures are collecte, and engineers mark samples. Learn the characteristics of different defects.

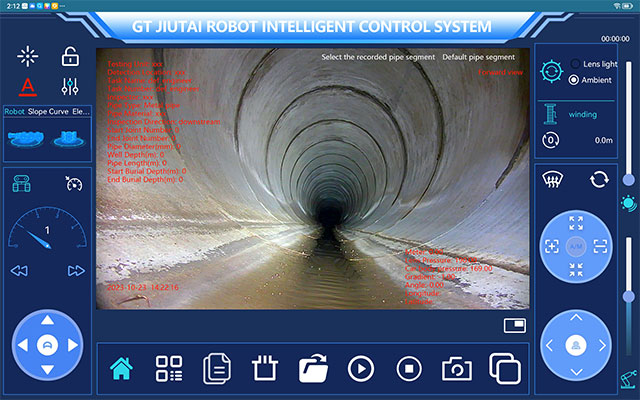

- Real-time inspection stage: The cctv pipe crawler robot is equipped with a 4-megapixel high-definition camera to videos or pictures of the pipe. The AI model analyzes the HD image frame by frame and locates the cracks through pixel-level segmentation technology.

Q4: Can AI distinguish cracks from pipe scratches?

Through multi-dimensional feature analysis:

- Shape: Cracks are mostly irregular lines, and scratches are usually straight and shallow.

- Texture: The edges of cracks are rough, and the surface of scratches is smooth.

- Depth: Combined with laser ranging data, determine whether it is structural damage.

Inspection case: How does AI inspection improve efficiency?

Case: Municipal drainage pipe inspection project

- Traditional method: A team of 3 people completed 10 kilometers of inspection in 2 weeks, with a missed detection rate of about 15%.

- After AI empowerment: The pipe inspection robot completed the full-segment inspect in 1 week, and AI generated an inspection report in real time.

- Key results: 2 high-risk cracks (width > 5mm) were found to avoid possible road collapse accidents.

Fourth, what else can AI do in the future?

- Pipeline maintenance: Predict the remaining life of the pipeline.

- Multi-sensor fusion: Combine sonar, laser, and gas identification sensors to identify risks or gas leaks.

- Cloud collaboration: Inspection data from various places are aggregate to the cloud to optimize management.

Conclusion

AI technology is driving pipeline inspection from "manual" to "intelligent". Zhengzhou Jiutai Technology's Pipe Vision AI series cctv pipe crawler robots have integrate intelligent identification systems. In the future, we will conduct in-depth research and continuous optimization.