The oil and gas industry faces big pressures: needs to keep pipes safe, make sure operations are reliable, and reduce costs. In this tough situation, Non-Destructive Testing (NDT) is more than just a inspection task for quality. It is becoming a key part of running things well, and this is making more people want better inspection equipments and technologies.

NDT: Keeping Oil and Gas Pipelines Safe with Internal Checks

Pipelines are like the main arteries of the oil and gas network. They stretch for thousands of kilometers and are very important. Non-Destructive Testing uses tools like pipe crawler robot cameras and borescopes push camera. These can go inside pipelines to check for problems like rust, cracks, dents, or bad welds. They also collect detailed information on how thick the pipe walls are and any possible flaws--all without stopping work. Operators find weak spots early, decide which maintenance work is most important, and stop expensive leaks or big accidents. It helps keep people and the environment safe, and it means pipelines can stay working longer.

Using Pipeline Inspection Robots to Hard to Reach Places

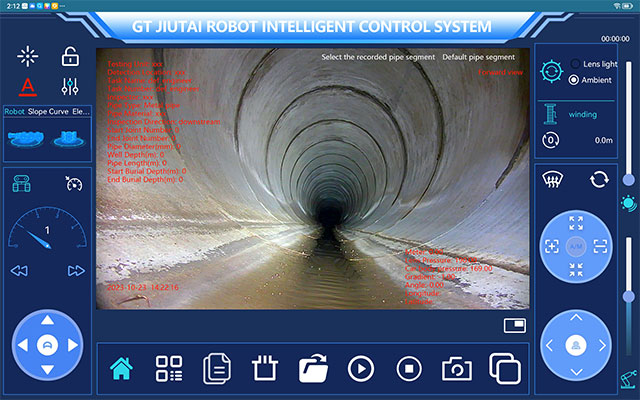

Complex underground pipeline networks—like small diameters pipe, complicated spaces inside—need more flexible inspect tools. Pipe inspection push camera or pipeline inspection crawler robots meet this need. These cctv pipe robots or cameras can move freely. They usually have HD cameras, controller unit, and reel cable . Inspectors control them into pipe inner. and inspect whether have any damages, weld defects or blockages in the pipeline. then also can phato or video, measure pipe thickness. Suitable for industrial pipelines, oil and gas pipes, or municipal pipes ect. This NDT technology offer important information for checking if the pipes are still in good condition.

Making More Demand with Better Safety, Efficiency, and Information

CCTV inspection robots are changing how we manage pipeline safety. These technologies do three main things:

- Reach new places: Pipe inspection robot can get to the areas that were impossible or too costly to inspection before.

- Collect inspect data: CCTV Pipe crawler camera produce clear, detailed inspect report about the pipe’s condition. This helps assess risks correctly.

- Fix problems early: They find issues soon, so workers can make targeted repairs before things break.

The Result: A Big Need for Advanced NDT Tools

These NDT technologies offer clear benefits: safer operations, following rules, making equipment last longer, and cutting operational costs. This is why pipeline inspection tools and robots are making demand grow in the oil and gas industry. Companies are starting to see that buying these CCTV pipe inspection camera system is not just a cost. It is something they must do to run reliably, efficiently, and responsibly. This trend will keep making more growth for companies that offer NDT solutions and know-how.