For many years, wind turbine blade inspection relied on manual. Inspector climbed high towers, with strong winds, it is very risky and slow.

Nowadays, Wind turbine blade inspection robots are becoming the more and more popular choice for wind farm, inspection companies, and project contractors. This change is not only a trend, but also it is a practical upgrade about by safety, efficiency, and cost.

As a professional manufacturer specializing in offer cctv inspection solutions and high quality product, Zhengzhou Jiutai Technology has found this change happened across Europe, the Middle East, South America, and Southeast Asia. More wind farm operators now request wind turbine blade inspection robotic tools instead of traditional Person maunal inspect. Here is why.

1. Safety is most important point

Climbing 100 meter turbine tower and working on a suspended rope has always exist large risk. Strong winds, weather changes, and equipment fatigue add to the danger.

CCTV inspection Robotic reduces these risks dramatically:

Technicians stay safely on the ground

CCTV Inspection Robots operate in stable and controlled conditions

The inspection process no longer depends on weather windows as strictly as rope access

For wind farm operators, fewer accidents mean lower insurance costs, less downtime, and higher compliance with safety standards.

2. Improve detection efficiency and reduce downtime

A person inspection normally takes 1–2 hours per turbine, sometimes more. If inspector need to cleaning or check multiple wind turbine blades, the time increases further.

In contrast, cctv wind blade inspection crawler can complete the same work in a much shorter time:

Faster ascent and descent

Automated scanning path

High-definition imaging collected in one pass

No repeated climbing or repositioning

For a large wind farm, saving even 30 minutes per wind turbine blade can reduce operational downtime significantly.

3. Higher Accuracy with Digital Records

One of the biggest advantages of robotic inspection is data consistency.

Robots capture:

High-resolution surface images

Fine cracks and erosion

Lightning strike marks

Leading edge wear

Gelcoat damage

Because the scanning path is controlled by software, the results are repeatable. Wind farm owners receive inspection reports regular that can be compared across months or seasons. This makes long-term maintenance planning more accurate and cost-effective.

4. Lower Long-Term Cost

Rope access requires trained climbers, climbing gear, safety vehicles, and strict weather monitoring. These costs add up.

A robotic inspection system like Jiutai’s reduces long-term expenses by:

Cutting labor intensity

Reducing climbing teams

Minimizing repeated inspections

Allowing quicker troubleshooting

Many overseas partners report that robotic inspection lowers their annual blade inspection cost by 20%–40%.

5. Growing Adoption Worldwide: Real Customer Cases

Case 1: European Wind Farm (Denmark)

A service company in Denmark used rope access for years. They switched to a robotic solution in 2024 because winter winds made climbing unsafe. After using Jiutai’s robot, they completed a 60-turbine inspection project two weeks faster than the previous year and with zero safety incidents.

Case 2: South American Contractor (Chile)

A Chilean maintenance contractor adopted a blade inspection robot to reduce labor dependency in remote mountain regions. The robot allowed them to perform inspections even when rope teams could not climb due to gusty winds. As a result, their seasonal maintenance schedule became more stable.

Case 3: Southeast Asia Coastal Wind Farms

In coastal regions with high humidity and frequent rain, rope access teams often struggled to find safe working windows. After switching to a robotic inspection system, the operator completed inspections during shorter weather intervals and reduced downtime by nearly 30%.

6. Why More Operators Choose Jiutai’s Blade Inspection Solutions

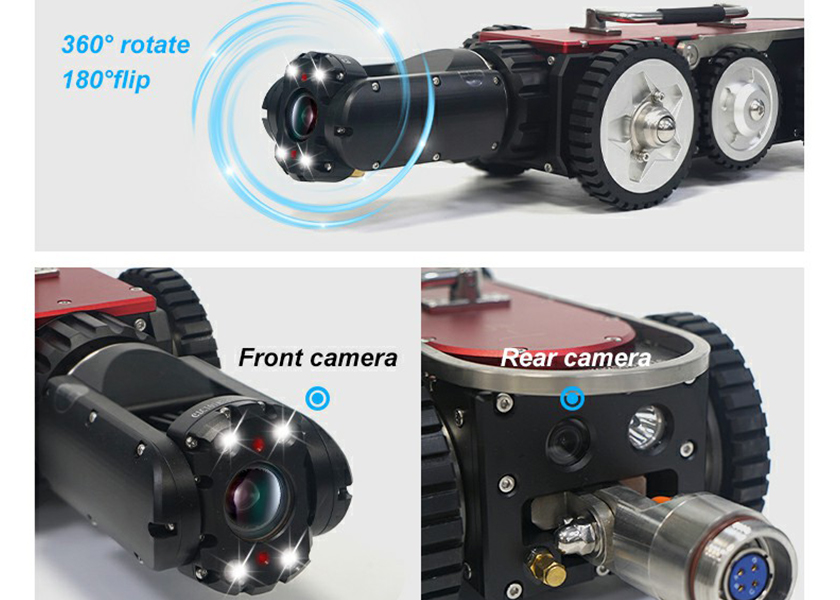

Jiutai Technology focuses on practical, field-ready inspection solutions. Our wind blade inspection robot is known for:

Strong wind resistance

High-resolution imaging

Stable magnetic adhesion

Easy operation

Lightweight structure for fast deployment

We design equipment for real working environments—mountain wind farms, offshore platforms, coastal towers, and desert regions. Our goal is simple: to help global wind farm operators maintain blades safely, accurately, and efficiently.

Conclusion

Using CCTV Wind Turbine blade inspection robots are the trend of future.

The industry is moving toward safer, faster and more intelligence maintenance methods.

For wind farm owners, engineering contractors, water Company and inspection companies, switching to robotic solutions means:

Better safety

Higher efficiency

More accurate damage assessment

Lower long-term cost

With the wind energy market grows, cctv inspection crawler robots will continue to play a key role in keeping turbines running smoothly.